Table of Contents

If you’re tired of constantly sharpening steel blades, you’re not alone. The promise of a blade that stays razor-sharp for extended periods is what draws many to ceramic blades. But do ceramic blades stay sharp as long as they claim?

Yes, ceramic blades stay sharp much longer than steel blades — up to 10x longer, according to experts. Their unique composition, extreme hardness, and resistance to corrosion make them one of the most reliable cutting tools for kitchens, crafting, and even industrial use. But there’s more to the story.

This article will explore what makes ceramic blades so effective at maintaining sharpness, the factors that affect their performance, and how to keep them sharp for as long as possible. We’ll also answer key questions and provide tips to help you get the most out of your ceramic blade.

What Makes Ceramic Blades Stay Sharp?

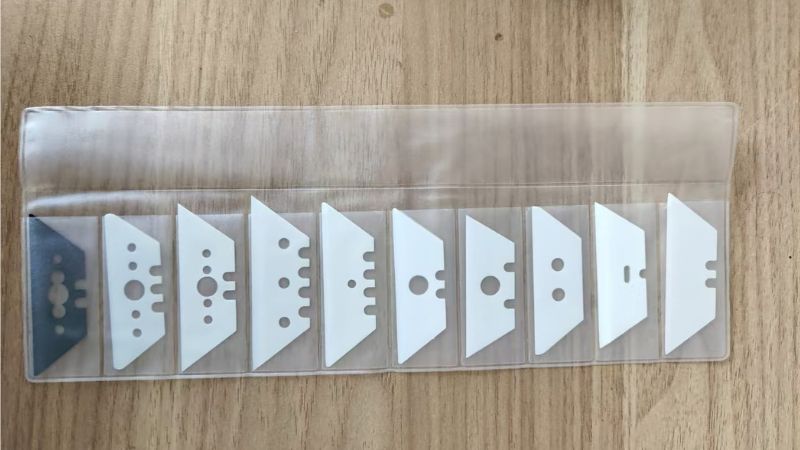

Ceramic blades are known for their long-lasting sharpness, but what sets them apart from steel blades? It comes down to two primary factors: material composition and blade design.

Material Composition

- Zirconium Oxide (ZrO2): The primary component of ceramic blades is zirconium oxide, a super-hard material that ranks 8.2 on the Mohs hardness scale. In comparison, most steel blades rank between 4 and 6. This hardness allows ceramic blades to maintain a sharper edge for a significantly longer time.

- High Wear Resistance: Unlike steel, ceramic is not affected by moisture, rust, or the acidity of foods like lemons or tomatoes. This prevents the blade from corroding or dulling over time, keeping it sharp for much longer.

Interesting Fact: The same zirconium oxide used in ceramic blades is also used in the production of dental implants and industrial cutting tools due to its extreme durability and resistance to wear.

Blade Design

- Precision Sharpening: Ceramic blades are manufactured with a highly precise sharpening process. The edge is ground to an ultra-fine, razor-sharp point that allows for clean and precise cuts.

- Edge Geometry: Unlike steel blades that may bend or warp over time, ceramic blades maintain a rigid, sharp edge. This design reduces friction, allowing for smoother, cleaner cuts.

| Feature | Ceramic Blades | Steel Blades |

|---|---|---|

| Hardness (Mohs) | 8.2 | 4-6 |

| Edge Retention | 10x longer | Shorter lifespan |

| Resistance to Rust | Yes | No (unless stainless) |

Key Takeaway: The unique combination of zirconium oxide’s hardness and the precision of the blade’s edge geometry gives ceramic blades their ability to stay sharp for significantly longer than steel blades.

How Long Do Ceramic Blades Stay Sharp?

One of the key selling points of ceramic blades is their ability to stay sharp far longer than traditional steel blades. But how long do they actually stay sharp? The answer depends on several factors, but in most cases, ceramic blades can stay sharp up to 10x longer than steel blades.

How Long Can You Expect Sharpness to Last?

- Light Use (Home Kitchen Use): In a typical home kitchen, where ceramic blades are used to cut fruits, vegetables, and boneless meats, the edge can stay sharp for 12-24 months or longer without needing to be sharpened.

- Industrial Use: In industrial or manufacturing settings, ceramic blades used for repetitive cutting tasks can maintain their edge for several months, whereas steel blades would require frequent resharpening.

- Crafting and Utility Use: In environments where precision cuts are needed (like crafting or DIY projects), the sharpness of a ceramic utility blade can last up to 3-6 months longer than a steel blade performing the same tasks.

| Use Case | Ceramic Blade Sharpness Duration | Steel Blade Sharpness Duration |

| Home Kitchen Use | 12-24 months (or more) | 2-4 months |

| Industrial Use | Several months | Weeks to 1 month |

| Crafting Use | 3-6 months | 1-2 months |

Pro Tip: Proper care and usage play a significant role in determining how long a ceramic blade will stay sharp. Avoid cutting bones, frozen foods, and other hard materials, as these can chip or dull the edge prematurely.

Why Do Ceramic Blades Stay Sharp So Long?

- Extreme Hardness: Ceramic’s hardness prevents micro-abrasions and edge deformation, unlike steel, which dulls faster due to wear.

- Corrosion Resistance: Steel can corrode or stain from exposure to water and acidic foods, leading to dulling. Ceramic blades are immune to rust and corrosion, keeping them sharper longer.

- Precision Edge Retention: Ceramic blades are sharpened to an ultra-fine edge that cuts cleanly, reducing edge wear and keeping the blade sharp longer.

Case Study: A chef who switched from steel to ceramic kitchen knives reported that while they needed to sharpen their steel blades every 2-3 months, their ceramic knife remained sharp for over a year with only light use.

Key Takeaway: Ceramic blades stay sharp 10x longer than steel blades due to their extreme hardness, resistance to corrosion, and advanced edge geometry. Proper use and care further extend their lifespan.

Why Do Ceramic Blades Stay Sharp for So Long?

Ceramic blades have a well-earned reputation for staying sharp for extended periods, but what’s the science behind it? The answer lies in three critical properties: material hardness, corrosion resistance, and edge geometry.

Material Hardness

- Zirconium Oxide’s Extreme Hardness: As mentioned earlier, zirconium oxide ranks 8.2 on the Mohs hardness scale, much harder than the steel used in traditional blades. Harder materials are less likely to wear down, making them capable of holding an edge for longer periods.

- Less Prone to Micro-Abrasions: While steel blades develop tiny abrasions during regular use, ceramic blades resist this wear due to their hardness. These micro-abrasions cause steel blades to dull faster, while ceramic blades maintain their fine edge.

Corrosion Resistance

- No Rust or Corrosion: Since ceramic is non-metallic, it’s immune to rust and corrosion. Steel blades, on the other hand, can corrode over time, especially when exposed to moisture, salt, or acidic foods.

- No Reaction with Acidic Foods: Cutting acidic foods like lemons, tomatoes, and citrus with steel blades can degrade the metal’s edge. Ceramic blades remain unaffected by these reactions.

How to Keep Ceramic Blades Sharp for Longer

Maintaining the sharpness of a ceramic blade requires careful handling, proper storage, and mindful usage. Although ceramic blades are renowned for their ability to stay sharp up to 10x longer than steel blades, a few best practices can make them last even longer.

Proper Usage Tips

- Avoid Cutting Hard Materials

- Do not use ceramic blades to cut bones, frozen foods, or hard materials like metal, stone, or hard plastics.

- Use the blade strictly for soft to medium-hard materials like fruits, vegetables, and boneless meat.

- Use a Soft Cutting Surface

- Always use a cutting board made of wood, bamboo, or plastic.

- Avoid cutting directly on hard surfaces like glass, ceramic, stone countertops, or metal trays, as these can chip the blade.

- Avoid Excessive Force and Twisting

- Apply only gentle pressure while cutting. Avoid using a sawing or twisting motion.

- Ceramic blades are rigid and brittle, and sudden forceful impacts can cause them to chip or break.

- Store Properly

- Store ceramic blades in a knife block, sheath, or drawer organizer to prevent accidental contact with other objects.

- Avoid placing them loosely in drawers where they can be bumped or knocked against other utensils, which may chip the blade.

Pro Tip: Investing in a protective sheath or a magnetic wall strip will protect your ceramic blades and keep them sharp for longer.

Cleaning and Maintenance

- Hand Wash Only

- Avoid dishwashers as the high temperatures and detergent chemicals can damage the blade.

- Wash ceramic blades by hand with warm, soapy water and a soft sponge.

- Dry Thoroughly

- Dry the blade immediately after washing to prevent water spots, although ceramic is rust-resistant.

- Use a soft towel to avoid scratching the surface.

- Inspect for Chips and Cracks

- Regularly check the edge for signs of chipping or cracking.

- If you spot a chip, avoid further use and consider getting the blade professionally sharpened or replaced.

Did You Know? While ceramic blades are rust-free, water spots can sometimes leave unsightly marks. Drying them thoroughly prevents this.

Sharpening a Ceramic Blade

- When to Sharpen

- Ceramic blades don’t require frequent sharpening, but if you notice a loss of cutting precision, it might be time for a tune-up.

- On average, a ceramic blade needs sharpening once every 1-3 years, depending on usage.

- How to Sharpen

- Use a diamond sharpening tool because traditional sharpening stones and tools are ineffective on ceramic.

- Alternatively, send your ceramic blade to a professional sharpening service that specializes in ceramic knives.

- DIY vs. Professional Sharpening

- DIY Option: Invest in a diamond sharpening rod or an electric ceramic blade sharpener.

- Professional Option: Many knife manufacturers offer mail-in sharpening services where your blade is honed by specialists.

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Washing | After each use | Prevents residue build-up |

| Drying | After washing | Avoids water spots |

| Storage | After each use | Protects blade from chipping |

| Sharpening | Every 1-3 years (or as needed) | Restores cutting performance |

Pro Tip: If you use ceramic blades daily for cooking, consider sending them for sharpening once every two years to maintain optimal sharpness.

What to Avoid When Using Ceramic Blades

- Avoid Dropping the Blade

- Ceramic is extremely hard but also brittle. If dropped, it can chip or break.

- Don’t Cut Frozen Foods or Bones

- Hard items like bones and frozen foods place excessive stress on the blade, leading to chips.

- Don’t Use Abrasive Cleaners

- Harsh scrubbers, scouring pads, or steel wool can scratch the surface of the blade.

Authoritative Source: According to Cutlery and More (https://www.cutleryandmore.com), professional chefs recommend using soft wooden cutting boards to protect the edges of high-end knives, including ceramic blades.

Do Ceramic Blades Ever Go Dull?

While ceramic blades are known for their superior edge retention, they are not immune to dulling. Over time, even the sharpest ceramic blades can lose their edge due to prolonged use, mishandling, or accidental damage.

Reasons Why Ceramic Blades Go Dull

- Micro-Chipping

- Ceramic blades are incredibly hard but also brittle. Small chips can form on the blade’s edge when it comes into contact with hard surfaces, such as bones, frozen foods, or metal countertops.

- These micro-chips create uneven edges, reducing cutting precision and making the blade feel dull.

- Improper Use

- Cutting inappropriate materials like hard bones, frozen foods, or metal objects can damage the blade.

- Twisting, bending, or applying lateral pressure to the blade increases the risk of chipping or breaking.

- Friction and Regular Wear

- While ceramic is significantly harder than steel, regular use will eventually wear down the edge of the blade.

- This wear process is slower than with steel blades but is still inevitable, especially with daily use in kitchens or industrial applications.

- Impact from Drops

- Dropping a ceramic blade on hard surfaces like tile, concrete, or stone can cause it to chip or shatter.

- These chips affect the blade’s sharpness and may require professional sharpening or blade replacement.

How to Tell If a Ceramic Blade Is Dull

- Reduction in Cutting Performance

- The blade struggles to slice through soft items like tomatoes, bread, or fruits.

- A sharp ceramic blade should glide through food effortlessly.

- Visual Inspection

- Look for small chips, nicks, or rough edges on the cutting edge.

- Chips may not always be visible to the naked eye, but they affect the blade’s performance.

- Cutting Feel

- If you feel resistance while cutting or have to use extra force, it’s a sign the blade’s sharpness has diminished.

Can a Dull Ceramic Blade Be Sharpened?

Yes, ceramic blades can be sharpened, but the process is different from sharpening steel blades. Due to the hardness of ceramic (ranking 8.2 on the Mohs hardness scale), traditional whetstones and sharpeners are ineffective. Here’s how you can sharpen a dull ceramic blade:

- Use a Diamond Sharpening Tool

- Diamond is one of the few materials harder than ceramic, making it suitable for sharpening.

- Use a diamond sharpening rod or a specialized electric sharpener designed for ceramic blades.

- Send It to a Professional Service

- If you don’t have the right tools, it’s best to send the blade to a professional sharpening service.

- Many manufacturers and retailers offer mail-in sharpening services for ceramic knives.

| Sharpening Option | Tools Required | Cost | Difficulty |

|---|---|---|---|

| DIY with Diamond Rod | Diamond sharpening rod | Low (one-time cost) | Moderate |

| Electric Sharpener | Electric ceramic blade sharpener | Medium | Easy |

| Professional Service | None (mail-in service) | Medium | Very Easy |

Pro Tip: If you use ceramic blades regularly, consider purchasing a diamond sharpening rod. It’s a small investment that can save time and money on professional sharpening services.

How to Prevent Ceramic Blades from Going Dull

- Use Proper Cutting Techniques

- Cut straight down without twisting or bending the blade.

- Use the appropriate tool for each task to prevent excessive wear on the blade.

- Avoid Hard Materials

- Do not use ceramic blades on bones, frozen food, or metal surfaces.

- Stick to cutting soft items like fruits, vegetables, and boneless meats.

- Store Blades Safely

- Place ceramic blades in a protective sheath or knife block to avoid accidental contact with other objects.

- Avoid placing ceramic knives loosely in drawers where they can bump into other utensils.

- Handle with Care

- Avoid dropping the blade on hard surfaces like stone or tile.

- Use a soft cutting board made from wood, bamboo, or plastic.

Authoritative Source: According to America’s Test Kitchen (https://www.americastestkitchen.com), the use of soft wooden cutting boards extends the lifespan of high-end kitchen knives, including ceramic blades.

Summary of Key Takeaways

| Cause of Dullness | How It Happens | How to Prevent It |

| Micro-Chipping | Contact with hard surfaces | Use soft cutting boards, avoid hard materials |

| Wear from Use | Natural wear from regular use | Use for soft items only |

| Improper Use | Cutting bones, frozen food | Use proper tools for each task |

| Impact from Drops | Dropping on hard surfaces | Handle with care, use blade guards |

Key Takeaway: Ceramic blades do eventually dull, but proper usage, safe handling, and routine maintenance can significantly extend their lifespan. If the blade becomes dull, sharpen it with a diamond tool or send it to a professional sharpening service.

Are Ceramic Blades Worth It?

Ceramic blades have become a popular choice for both home and industrial use, but are they truly worth it? To answer this, it’s essential to weigh the benefits and drawbacks of ceramic blades compared to traditional steel blades.

Benefits of Ceramic Blades

- Long-Lasting Sharpness

- Ceramic blades stay sharp 10x longer than steel blades, meaning less frequent sharpening and less maintenance overall.

- This is especially useful for kitchen knives, box cutters, and utility blades used in crafting or industrial settings.

- Corrosion Resistance

- Ceramic blades do not rust, unlike steel blades, which can corrode when exposed to water, acidic foods, or humidity.

- This makes them ideal for kitchen use where exposure to moisture is unavoidable.

- Hygiene and Food Safety

- Because ceramic is a non-porous material, it doesn’t absorb food particles, bacteria, or odors like steel.

- This is why ceramic knives are preferred in food preparation environments that prioritize hygiene.

- Precision Cutting

- The sharper edge and fine-tuned geometry of ceramic blades result in smoother, cleaner cuts.

- This makes them perfect for slicing fruits, vegetables, and delicate ingredients without crushing or tearing them.

- Lightweight and Easy to Handle

- Ceramic blades are much lighter than steel, making them easier to handle and reducing user fatigue, especially during extended use.

- Non-Magnetic and Non-Conductive

- Unlike metal blades, ceramic blades are non-magnetic and do not conduct electricity.

- This makes them a safer option for industries that work with electronics or magnetic-sensitive equipment.

| Benefit | Description |

|---|---|

| Edge Retention | Stays sharp 10x longer than steel |

| Rust-Resistance | 100% resistant to rust and corrosion |

| Hygienic | Non-porous surface resists bacteria and odors |

| Lightweight | Lighter and more comfortable to use |

| Non-Conductive | Safe to use near electronics and sensitive equipment |

Drawbacks of Ceramic Blades

- Brittle and Prone to Chipping

- Ceramic’s extreme hardness makes it brittle. If dropped on a hard surface, the blade may chip or shatter.

- Chips on the cutting edge reduce performance, requiring professional sharpening or replacement.

- Not Suitable for Hard Materials

- Ceramic blades are not designed for cutting through bones, frozen food, or other hard objects.

- Misusing the blade in this way can result in chips or cracks.

- Limited Versatility

- Steel blades are more versatile in their range of applications. Steel blades can cut bones, frozen food, and tough materials, but ceramic blades cannot.

- Difficult to Sharpen at Home

- Ceramic’s hardness means that standard sharpeners won’t work. Sharpening requires a diamond sharpening tool or a professional sharpening service.

- DIY sharpening can be challenging and time-consuming for those unfamiliar with the process.

- Higher Initial Cost

- Ceramic blades cost more than standard steel blades.

- However, since they stay sharp longer, they may save money over time by reducing the need for replacements and sharpening services.

| Drawback | Description |

| Brittle | Can chip or shatter if dropped on hard surfaces |

| Not Versatile | Not suitable for cutting hard items like bones |

| Challenging to Sharpen | Requires a diamond tool or professional service |

| High Initial Cost | More expensive upfront than steel |

When Should You Choose a Ceramic Blade?

Ceramic blades are best for specific use cases, especially when you need precise, hygienic cuts with minimal maintenance. Here’s when you should choose a ceramic blade:

- Food Preparation

- If you prepare fresh fruits, vegetables, and boneless meats regularly, ceramic blades are perfect for you.

- Their ability to maintain sharpness and prevent bacterial growth makes them ideal for kitchens and food prep areas.

- Crafting and DIY Projects

- Precision cuts required for paper, fabric, and crafting materials are ideal for ceramic utility blades.

- Since they are lighter and provide smoother cuts, they’re a favorite for artists and DIY enthusiasts.

- Industrial Use

- Industrial settings that require repetitive precision cuts benefit from ceramic box cutters and utility knives.

- Workers in the packaging industry or electronics sector often prefer ceramic blades since they’re non-conductive and non-magnetic.

- Electronics and Magnetic-Sensitive Areas

- Unlike steel blades, ceramic blades do not conduct electricity or interfere with magnetic-sensitive equipment.

- For this reason, they’re used in aerospace, automotive, and electronics manufacturing.

Key Takeaway: Ceramic blades are worth it if you value sharpness, hygiene, and rust resistance. They’re perfect for kitchens, crafting, and industrial use. However, for heavy-duty tasks like cutting frozen foods or bones, steel blades remain the superior choice.

Authoritative Source: According to Consumer Reports (https://www.consumerreports.org), ceramic knives are preferred by professional chefs for their superior sharpness and resistance to rust, making them an essential kitchen tool.

FAQ About Ceramic Blades

How long do ceramic blades stay sharp?

Ceramic blades stay sharp up to 10x longer than steel blades. With proper usage, they can maintain their sharpness for 12-24 months or more, especially in home kitchens where they’re used for fruits, vegetables, and boneless meats.

Can ceramic blades be sharpened?

Yes, but not with standard sharpeners. Ceramic blades require a diamond sharpening tool or a professional sharpening service. DIY sharpening is possible with the right equipment, but many users opt for professional services.

Do ceramic blades chip easily?

Ceramic blades are extremely hard but also brittle, meaning they can chip if dropped on hard surfaces or used to cut hard objects like bones, frozen food, or hard plastics. Proper care and storage can prevent chipping.

Are ceramic blades better than steel blades?

It depends on the intended use. Ceramic blades stay sharper longer and are rust-proof, lightweight, and hygienic. Steel blades are more versatile, impact-resistant, and easier to sharpen at home. For delicate cuts, ceramic is ideal, but for heavy-duty tasks, steel is better.

Do ceramic blades rust?

No, ceramic blades are 100% rust-proof because they are made from non-metallic materials like zirconium oxide. Unlike steel, they do not corrode or react to moisture, making them ideal for kitchen use.

Can ceramic blades cut bones or frozen food?

No, ceramic blades are not designed to cut through bones, frozen food, or other hard objects. Doing so can result in chips, cracks, or complete breakage of the blade’s edge.

How do I store a ceramic blade properly?

Store ceramic blades in a knife block, protective sheath, or drawer organizer. Avoid placing them loosely in a drawer where they can bump into other utensils, as this may cause chipping.

Can I use a ceramic blade for meat and fish?

Yes, ceramic blades are excellent for cutting boneless meat and fish. However, avoid using them on bones, as this can chip the edge.

How do I know if my ceramic blade needs sharpening?

If you notice increased resistance while cutting or see visible chips or nicks on the blade’s edge, it’s time for sharpening. A ceramic blade should glide smoothly through soft materials without excessive force.

What’s the difference between a ceramic blade and a steel blade?

| Feature | Ceramic Blade | Steel Blade |

|---|---|---|

| Sharpness | Stays sharp 10x longer | Dulls faster, requires frequent sharpening |

| Durability | Brittle, can chip if dropped | More impact-resistant |

| Rust Resistance | 100% rust-proof | Can rust without proper care |

| Weight | Lightweight and easy to handle | Heavier |

| Maintenance | Rare sharpening required | Requires frequent sharpening |

What materials can ceramic blades cut?

Ceramic blades excel at cutting soft to medium-hard materials like:

- Fruits (apples, oranges, lemons)

- Vegetables (tomatoes, cucumbers, carrots)

- Boneless meat and fish

- Paper, fabric, and thin packaging materials

Avoid cutting hard objects like bones, frozen food, and metal, as these can damage the blade.

How often should I sharpen a ceramic blade?

Ceramic blades require sharpening once every 1-3 years, depending on usage. Since they maintain sharpness 10x longer than steel, sharpening is a rare task. Use a diamond sharpener or seek a professional sharpening service.

Can I cut citrus fruits with a ceramic blade?

Yes, ceramic blades are perfect for cutting citrus fruits. Unlike steel, ceramic does not react to acidic foods, preventing staining, corrosion, or transfer of metallic taste to the fruit.

Conclusion

Ceramic blades offer exceptional sharpness, edge retention, and resistance to rust. While they stay sharp up to 10x longer than steel, proper care and maintenance are essential to maximize their lifespan. Ideal for kitchens, crafts, and industrial use, ceramic blades are a worthwhile investment for precision cutting and long-term performance.