Table of Contents

In recent times, ceramic blades have become more popular in households and some industries because they are light, sharp and do not rust. Is it true that ceramic blades need oiling? This is one of the questions people have on the maintenance of ceramic blades. This is understandable when one considers the fact that unlike steel blades, ceramic blades have different characteristics.

No. There is no need to oil ceramic blades. They are extremely low maintenance because of their non-porous surface and resistance to corrosion. At the same time, it is vital that such blades are cleaned and stored properly to ensure durability and edge retention.

A Deeper Understanding of Ceramic Blades

Essentially, ceramic blades are made out of zirconium oxide. Out of all cutting tools available, these blades are the best for cutting operations with a reasonable weight on them but care should be taken as they are prone to breaking under mishandling.

What Makes Ceramic Blades Unique?

- Hardness – When it comes to hardness, steel is the absolute second best after diamonds; however, it can certainly retain its edge longer; in some cases, around ten times longer than steel.

- Non-Corrosive – Another distinctive feature between steel and ceramic is that there’s no chance for ceramic to rust and corrode regardless of how much moisture it is subjected to.

- Lightweight – Ceramic blades are significantly lighter, reducing hand fatigue during repetitive tasks.

Types of Ceramic Blades

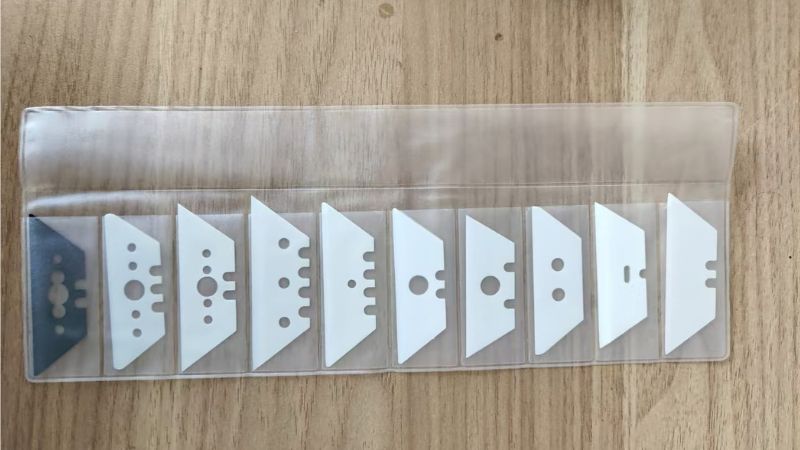

According to JCK Cutter a variety of ceramic blades are available one can easily choose the one fitting best to their job;

- Utility Knife Blades – Ideal for everyday cutting tasks, providing sharp, clean cuts.

- Single Razor Blades – Used in industrial and medical applications for extreme precision.

- Scalpel Blades – Common in surgical settings for accuracy and sterility.

- Slitting Blades – Suited for cutting through packaging and textiles.

- Hook Blades – Designed for cutting through heavy-duty materials without damaging underlying surfaces.

| Type of Ceramic Blade | Application |

|---|---|

| Utility Knife Blades | Everyday cutting |

| Razor Blades | Industrial, medical |

| Scalpel Blades | Surgical, precise tasks |

| Slitting Blades | Packaging, textiles |

| Hook Blades | Heavy-duty cutting, protective cuts |

How Ceramic Blades Differ from Steel Blades

| Feature | Ceramic Blades | Steel Blades |

| Corrosion Resistance | 100% – No rust | Requires oiling to prevent rust |

| Sharpness Retention | Longer-lasting edge | Dulls faster, needs regular honing |

| Weight | Lightweight | Heavier |

| Durability (Impact) | Brittle, can chip | More flexible and durable |

| Maintenance | Low – No oil needed | High – Requires oil and upkeep |

Essentially, people prefer using these trapezoidal blades since they are highly durable and compliant with low maintenance. Therefore, they are primarily focused in kitchens, medical fields and other industrial usage.

Do Ceramic Blades Require Oil?

Unlike steel blades, ceramic blades generally do not require oil for maintenance or performance. This distinction comes from the differences in material properties and blade composition.

Why Traditional Blades Need Oil

Steel blades are prone to rust and corrosion, which can significantly shorten their lifespan and reduce their sharpness. Oil acts as a protective barrier, preventing moisture from causing oxidation. Additionally, oil can:

- Reduce Friction – By lubricating the blade, cutting becomes smoother and easier.

- Prevent Rust – A thin layer of oil repels water, keeping the steel surface protected.

- Enhance Longevity – Regular oiling preserves the blade’s edge and prevents pitting or surface degradation.

Are Ceramic Blades Exempt from Oiling?

Ceramic blades, made from zirconium oxide, naturally resist rust and corrosion, making oil unnecessary for protective purposes. The non-porous surface of ceramic blades prevents moisture absorption, which eliminates the need for oil as a barrier.

Key Reasons Ceramic Blades Don’t Require Oil:

- Rust-Free – Ceramic does not oxidize or rust.

- Non-Stick Properties – The smooth surface reduces friction without additional lubrication.

- Maintenance-Free – Basic cleaning and careful storage are enough to keep ceramic blades in optimal condition.

| Blade Type | Oil Required? | Reason |

|---|---|---|

| Steel Blades | Yes | Prone to rust and corrosion |

| Ceramic Blades | No | Naturally rust-resistant and non-porous |

| High Carbon Steel Blades | Yes | Susceptible to moisture damage |

When Oil Can Be Used (Optional)

While ceramic utility knife blades don’t require oil, some users apply a light coating to enhance cutting performance in specialized applications, such as:

- Food Prep – Applying a thin layer to reduce drag when slicing sticky foods.

- Industrial Use – In high-friction environments, oil may reduce resistance slightly.

However, this practice is rare and often unnecessary for general use. Proper handling and storage are typically sufficient to maintain ceramic blade quality.

Advantages of Not Using Oil on Ceramic Blades

The most impressive feature of ceramic blades is their ability to operate without the necessity of using oils. This allows them, in addition to their effectiveness, to achieve an excellent long-term performance and ease of use. This peculiar peculiarity sets them apart from steel blades and makes them very popular among kitchen users whether at home or in a professional setting.

Corrosion Resistance

Ceramic corrosion is a phenomenon that occurs through chemical deterioration. This suggests that they do not undergo chemical deterioration like steel blades that give rise to rust which makes them self defensive. Furthermore, since a layer of rust is not formed, protective oils are not needed.

- Fact: Ceramics such as zirconium oxides do not have oxygen or water chemically bound to them and hence do not rust.

- Benefit: Ceramic blades allow the users to rinse them in water at once, without the fear of the moisture damaging the material.

Non-Porous Surface Benefits

It has also been proven that ceramic blades are more hygienic and easy to take care of because they resist aversive stains, smell and food debris due to the blades having a non-porous surface.

- Benefit: Food constituents do not penetrate into the ceramic blades as it happens with steel blades where oil, juice or food tastes absorb.

- Result: Cuts are performed clean without transfer of each food constituent to every cut of the ingredient.

| Feature | Ceramic Blades | Steel Blades |

| Corrosion Resistance | 100% – No rust | Prone to rust |

| Surface Porosity | Non-porous – No odor retention | Absorbs oils and odors |

| Cleaning Requirements | Simple – No oil needed | Requires regular oiling |

Low Maintenance Requirements

With regards to a blade’s maintenance, ceramic blades do not require oiling as frequently.

- Ease of Care: Simple hand washing and careful storage are sufficient to keep ceramic blades sharp and functional.

- Cost-Effective: Reduces the need for additional blade oils or specialty cleaners.

According to Slice Products, ceramic blades will last approximately 11 times longer than steel blades making them a good cutting solution with great longevity and little maintenance requirements.

How to Maintain Ceramic Blades Without Oil?

Ceramic blades need to be maintained for sharpness in order to be able to keep using for a long time. However, ceramic blades should be regularly cared for to avoid chipping, cracking, or dulling (although they don’t require oil like metal knives). Here are some effective oil-free ways to maintain ceramic blades in great condition

Proper Cleaning Methods

Ceramic blades are also easy to clean but they should be cleaned with care to avoid accidental damage. Ceramic blades naturally hygienic due to their non-porous surface, resistant to stains or bacterial buildup..

Step by step guide: How to clean ceramic blades?

- Hand Wash Only – Use warm, soapy water and a nonabrasive sponge to clean the blade.

- Avoid Abrasive Materials –No steel wool, scouring pads, or hard-bristle brushes.

- Dry Immediately – Use a soft cloth to dry the blade right after washing. This prevents accidental drops and chipping.

- No Dishwashers – The intense environment of dishwashers, including high heat and contact with other utensils, can lead to chipping or cracking.

| Task | Recommended Method | Avoid |

|---|---|---|

| Washing | Hand wash with soft sponge | Dishwasher, scouring pads |

| Drying | Dry immediately with soft cloth | Air drying (risk of accidental damage) |

| Deep Cleaning (Stains) | Baking soda paste + gentle scrub | Harsh chemical cleaners |

Storage Recommendations

In order to keep ceramic blades chip-free and crack-free, it is important to store them correctly. Ceramic knives are brittle so they can snap if not stored or used properly, unlike steel knives.

Best Storage Practices:

- Knife Block or Sheath – Use a knife block or sheath for ceramic knives to keep the blade safe.

- Magnetic Strips (Ceramic-Safe) – Certain magnetic strips are made especially for holding ceramic blades. Make sure that the magnet is soft and padded to avoid hard hits.

- Avoid Stacking – Do not store ceramic blades loose in a drawer along with other knives or utensils. This can cause a chipping action if they impact with each other.

| Storage Method | Suitability for Ceramic Blades |

|---|---|

| Knife Block | Excellent |

| Sheath | Excellent |

| Magnetic Strip (Ceramic-Safe) | Good |

| Loose in Drawer | Not Suitable |

Preventing Chipping and Breakage

Ceramic blades are durable but they are also brittle. Improper handling could make them chip prone.

Tips to Prevent Chipping:

- Cut on Soft Surfaces – Use wooden or plastic cutting boards. Avoid glass, marble, or granite surfaces.

- Avoid Twisting Motions – Ceramic blades are designed for straight cuts. Twisting or prying can lead to fractures.

- Do Not Cut Hard Materials – Avoid cutting frozen foods, bones, or hard vegetables like squash with ceramic blades.

Surfaces to Avoid:

- Glass cutting boards

- Stone countertops

- Ceramic plates

Fact: According to Kyocera, one of the largest ceramic knife manufacturers, over 80% of ceramic knife damage occurs from improper cutting surfaces or accidental drops.

When Would Some Oil May Help for Ceramic Blades?

Although ceramic blades require very little maintenance, there are some exceptional cases in which rubbing a thin layer of oil in can bring short-term benefits. Such cases—infrequent, but they do exist—are usually linked to improved cutting performance and/or temporary protection during storage or transport.

Tips for Cuttin Sticky Foods WIth Smooth Cuts

During food preparation, sticky items such as dried fruit, cheese or fatty meat might stick to the blade, creating friction and uneven cuts. A thin coat of food-safe oil will lessen friction for more even slicing.

When to Use Oil for Food Preparation:

- Cheese Slicing – Soft cheeses adhere to the blade and making nice cuts can be difficult.

- Dried Fruits – Sticky textures from dates, apricots, and figs benefit from minimal lubrication.

- Fatty Meats – Ceramic blades can slice thin cuts smoothly. Slicing through a duck or pork belly can lead to difficulty due to ribbing.

Recommended Oils for Food Use:

- Mineral Oil (Food-Grade) – Odorless and safe for consumption.

- Vegetable Oil – One coat does the job but you may need to apply this again and again.

| Food Type | Benefit of Oil Application |

|---|---|

| Soft Cheese | Reduces sticking, ensures clean cuts |

| Dried Fruits | Prevents drag and uneven slices |

| Fatty Meats | Smooth slicing with minimal resistance |

Protective Coating for Industrial Use

Ceramic blades are sometimes used in fabrics, composite, and plastic cutting in an industrial environment. A thin coating of oil can decrease surface area contact which overtime, reduces the wear and tear of the blade allowing it to complete high friction tasks for longer..

Industries That May Use Oiled Ceramic Blades:

- Textile Manufacturing – Reduces resistance when cutting through layered fabrics.

- Automotive Production – When penetrating through rubber gaskets s or components made of plastic is easier.

Tip: Use light machine oil or silicone-based lubricants for industrial applications to prevent material buildup on the blade.

Temporary Rust-Free Coating (When Ceramic Blades Have Metal Components)

Though the ceramic portion of the blade is rust-proof, some hybrid ceramic knives

incorporate metal components in their handles or joints. In such cases, applying oil to the metal parts can prevent corrosion, preserving the knife’s overall integrity.

| Blade Material | Oil Needed? |

|---|---|

| Pure Ceramic | No – Fully rust-resistant |

| Ceramic with Metal Bolster | Yes – Protect metal components |

| Hybrid Ceramic-Steel | Yes – Metal portion needs oiling |

How to Apply Oil Correctly

When oiling is necessary, follow these steps to avoid over-application:

- Clean the Blade – Wash and dry the blade thoroughly before applying oil.

- Apply a Small Amount – Use a soft cloth or paper towel to apply a drop of oil along the blade’s surface.

- Wipe Off Excess – Ensure no excess oil remains to prevent slippery handling.

- Store Properly – Place the oiled blade in a protective sheath or knife block to avoid dust accumulation.

FAQ About Ceramic Blade Maintenance

Do ceramic blades rust without oil?

No. Ceramic blades are rust-proof and naturally resistant to corrosion. Their non-metallic composition eliminates the need for oil as a rust-prevention method.

Will oiling a ceramic blade improve its performance?

Oiling ceramic blades offers no performance benefit. Ceramic blades already have a non-stick, low-friction surface, allowing for smooth cuts without lubrication.

Can oil prevent chipping on ceramic blades?

No. Chipping occurs due to improper handling, cutting hard materials, or dropping the blade. Oil does not provide any structural reinforcement to prevent chipping.

Is there any situation where oiling a ceramic blade is recommended?

While unnecessary for most cases, a light coat of food-safe oil may reduce sticking when cutting highly adhesive foods like cheese or dried fruits.

Can ceramic blades dull over time?

Yes, but they stay sharp significantly longer than steel blades. However, improper use (e.g., cutting bone or frozen items) can accelerate dulling.

Are ceramic blades more fragile than steel blades?

Yes. While harder than steel, ceramic blades are more brittle and prone to chipping if dropped or used to cut hard materials.

How often should ceramic blades be sharpened?

Ceramic blades rarely need sharpening, but if dullness occurs, use a diamond sharpening stone specifically designed for ceramic blades.

Conclusion

Ceramic blades offer rust-free, low-maintenance performance without the need for oil. Their durability and sharpness last longer than steel, but careful handling and proper storage are essential to prevent chipping. By following basic care practices, ceramic blades can remain reliable, high-performing tools for years.