Table of Contents

Are you tired of constantly sharpening your kitchen knives, industrial cutting tools, or craft blades? Do you wonder if there’s a better option that stays sharp for longer, is rust-resistant, and requires minimal maintenance? If so, you’re not alone.

Yes, ceramic blades are better in many situations. Their unmatched sharpness, incredible edge retention, and resistance to rust and chemicals make them a top choice for precision work, hygiene-sensitive environments, and industries requiring durable, long-lasting blades.

However, the answer isn’t always that simple. While ceramic blades excel in some areas, they fall short in others. In this blog, we’ll take a closer look at ceramic blades vs. steel blades, exploring which one is truly better depending on specific applications, like kitchen use, industrial cutting, and medical tools.

What Are Ceramic Blades?

Ceramic blades are cutting tools made from advanced ceramics, primarily zirconium oxide. This material is known for its extreme hardness, wear resistance, and chemical inertness. Unlike steel blades, ceramic blades are not metallic, which gives them distinct properties like being non-conductive and non-magnetic.

How do ceramic blades differ from steel blades?

While steel blades rely on metal alloys to achieve strength and flexibility, ceramic blades are created from zirconium oxide through a process called sintering. This process makes them incredibly hard, ranking 8.2 on the Mohs hardness scale, which is much harder than steel.

What’s the Types of Ceramic Blades?

Kitchen Knives: Widely used in food preparation, ceramic kitchen knives excel at slicing fruits, vegetables, and boneless meat. Their superior sharpness reduces the need for frequent sharpening.

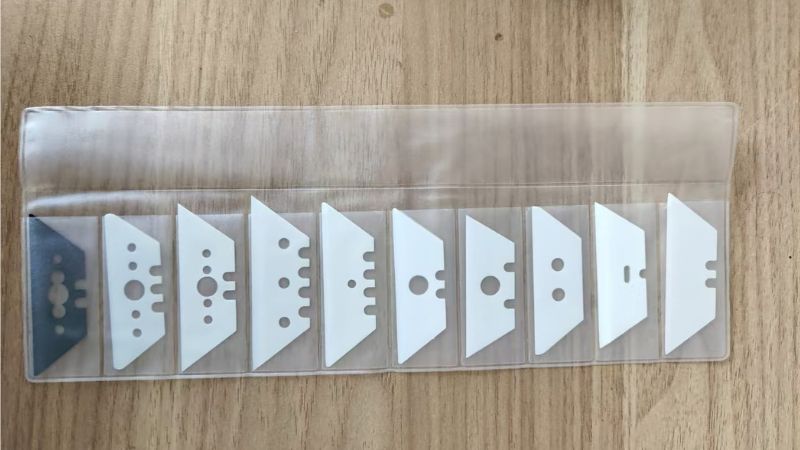

Utility and Craft Blades: Used for precision tasks like cutting paper, fabric, and packaging materials. Ceramic trapezoidal blades are common in crafting and utility knives.

Industrial and Textile Blades: Ceramic blades for textile cutting are essential in industries where sharp, durable blades are required to handle repetitive, precision cuts.

Medical and Surgical Blades: Often used in medical instruments, surgical tools, and laboratory applications where non-conductive blades and chemical resistance are critical.

How Are Ceramic Blades Made?

The Manufacturing Process:

- Raw Material Preparation: The process begins with zirconium oxide powder, which is mixed with binders to form a moldable material.

- Shaping and Molding: The ceramic material is pressed into molds to achieve the desired blade shape.

- Sintering: The molded blades are heated at high temperatures to harden them into a dense, durable form.

- Finishing and Polishing: The edges are sharpened and polished to create a precise cutting edge.

Why This Process Matters: The sintering process increases blade density, making ceramic blades incredibly hard and resistant to wear. However, this process also increases their brittleness, meaning they can chip or crack if dropped or twisted.

What’s The Key Properties of Ceramic Blades?

Extreme Hardness: Ceramic blades are significantly harder than steel.

Lightweight Design: Ceramic blades are much lighter than steel, reducing hand fatigue during use.

Rust-Resistant: Ceramic blades are impervious to rust, unlike metal blades.

Non-Conductive and Non-Magnetic: Ideal for use in electronics and medical tools where electrical conductivity and magnetic interference must be avoided.

| Property | Ceramic Blades | Steel Blades |

|---|---|---|

| Material Composition | Zirconium Oxide | Metal Alloys |

| Hardness (Mohs Scale) | 8.2 | 5-6 |

| Rust Resistance | Yes | No (unless stainless) |

| Weight | Lightweight | Heavy |

| Brittleness | High | Low (flexible) |

Expert Insight: “Ceramic blades are unmatched in sharpness and longevity, making them indispensable in precision cutting and food prep. However, proper care is essential to avoid chipping.” — Dr. John Taylor, Materials Science Specialist

How Do Ceramic Blades Work?

Cutting Edge Sharpness

Why are ceramic blades sharper than steel blades?

Ceramic blades maintain a sharper edge for longer because of their extreme hardness. Since they are less prone to bending or warping, the edge remains precise for extended periods.

Comparison with Other Blade Materials

Unlike steel blades that require frequent sharpening, ceramic blades can maintain their edge for up to 10 times longer. Steel blades, on the other hand, lose sharpness due to wear and deformation over time.

Hardness and Brittleness

Blade Hardness

Ceramic blades rank 8.2 on the Mohs scale, making them harder than most steel blades. This hardness allows ceramic blades to cut through delicate materials with ease but also makes them more brittle.

Blade Brittleness

Hardness comes at a cost — brittleness. Unlike flexible metal blades, ceramic blades can chip or crack if exposed to lateral force or impact. This is why ceramic blades are best for straight, precise cuts rather than heavy-duty chopping.

Resistance to Wear and Corrosion

Rust Prevention

Ceramic blades are naturally resistant to rust and corrosion since they do not contain metal. This makes them ideal for wet environments or tasks involving acidic foods like citrus fruits.

Wear Resistance

Since ceramic blades don’t oxidize or degrade, they maintain their appearance and sharpness for longer periods than traditional steel blades.

| Property | Ceramic Blades | Steel Blades |

| Sharpness Retention | Up to 10x longer | Requires frequent sharpening |

| Brittleness | High (can chip) | Low (more flexible) |

| Rust Resistance | Yes | No (unless stainless) |

| Durability | Hard but brittle | Tough, flexible |

Pro Tip: To maintain the performance of ceramic blades, avoid using them on hard surfaces like glass, stone, or metal. Use them exclusively for slicing softer materials like fruits, vegetables, and boneless meats.

Advantages of Ceramic Blades

Ceramic blades are rapidly becoming a preferred choice for both household and industrial cutting tasks. Their growing popularity stems from their impressive sharpness, long-lasting edge retention, and resistance to wear. To provide a clearer picture of their advantages, let’s delve into some of the key benefits of ceramic blades:

Stays Sharper, Longer

One of the biggest benefits of owning a ceramic blade is its ability to stay sharper for longer compared to steel blades. The ceramic material’s hardness plays a significant role in its superior edge retention.

Hardness Factor

Ceramic blades are made from zirconium oxide, which has a Mohs hardness rating of 8.2. This is significantly harder than most steel blades, which typically rank between 5-6 on the Mohs scale. This extreme hardness translates directly into the blade’s ability to maintain its sharp edge for a much longer period, even with heavy use.

Longer Cutting Efficiency

Ceramic blades can remain sharper up to ten times longer than their steel counterparts. This makes them an ideal choice for tasks requiring sustained sharpness, such as in food preparation, textile cutting, and industrial applications where precision is critical.

Sharper Initial Edge

Due to their hardness, ceramic blades also come with an initially sharper edge than steel blades. This provides users with a smoother and more effortless cutting experience right out of the box.

| Feature | Ceramic Blades | Steel Blades |

|---|---|---|

| Hardness (Mohs Scale) | 8.2 | 5-6 |

| Edge Retention | Up to 10 times longer | Requires frequent sharpening |

| Initial Sharpness | Sharper initially | Slightly duller initially |

| Durability | Excellent wear resistance | Prone to wear and dullness |

Quote: “Ceramic blades not only provide superior sharpness but their ability to retain that edge longer than steel makes them invaluable in industries where precision and longevity matter.” – Jane Woodson, Cutting Tool Expert

Resistant to Rust and Corrosion

Another notable advantage of ceramic blades is their resistance to rust and corrosion. Unlike steel blades, which are susceptible to oxidation and corrosion, ceramic blades are completely impervious to these issues.

Rust-Free

Ceramic blades do not rust, no matter the environmental conditions. This makes them ideal for kitchen use, particularly in environments where food might come into contact with the blade, as it eliminates the risk of metallic taste or contamination.

Ideal for Wet Conditions

Their rust-resistant properties make ceramic blades a great option for use in moist or humid environments, such as in marine settings, or for cutting tasks involving wet materials.

| Feature | Ceramic Blades | Steel Blades |

|---|---|---|

| Rust Resistance | Yes, completely rust-resistant | Susceptible to rust |

| Corrosion Resistance | No corrosion | Corrodes over time |

| Suitability for Wet Use | Excellent in wet conditions | Needs regular maintenance |

Lightweight and Easy to Handle

Ceramic blades are much lighter than their steel counterparts, which can be a key factor in reducing fatigue during prolonged use.

- Hand Fatigue Reduction: The lightweight design of ceramic blades helps reduce hand and wrist fatigue, especially during long cutting sessions. This is particularly useful in industries like textile cutting and medical fields, where precision cutting is required over extended periods.

- Ergonomics: The reduced weight also allows for better control and precision, which is especially beneficial for detailed work.

Chemical Resistance and Hygiene

Because ceramic blades are made of non-reactive materials like zirconium oxide, they are highly resistant to many chemicals.

- Non-Reactive: Ceramic blades don’t react with acidic or alkaline substances. This makes them ideal for food preparation tasks, as they will not alter the taste, smell, or appearance of foods.

- Hygiene Benefits: Ceramic blades are also non-porous, which means they won’t absorb bacteria, odors, or stains from cutting materials. This makes them especially useful in hygiene-sensitive environments like kitchens, hospitals, or cleanrooms.

Sharpness and Precision for Specialized Tasks

The unparalleled sharpness of ceramic blades allows them to excel in precision tasks that require a fine cutting edge.

- Food Preparation: Ceramic knives are highly effective in slicing fruits, vegetables, boneless meats, and other delicate foods without squashing or bruising them. Their sharpness allows for thin, even cuts, ideal for presentations or specific culinary applications.

- Industrial Cutting: Ceramic slitting blades are used in industries where precision cutting of materials like films, textiles, and packaging is essential. Their ability to stay sharp without frequent re-sharpening makes them a valuable tool in production lines.

Superior Edge Retention – A Cost-Effective Option

Although ceramic blades may come with a higher upfront cost, their long-term cost-effectiveness is undeniable.

- Longer Lifespan: Since ceramic blades stay sharper longer, they require less frequent sharpening or replacement compared to steel blades. This results in significant cost savings over time, particularly in industries with high-volume cutting.

- Minimal Maintenance: With ceramic blades, you won’t need to worry about rust maintenance, and their durability means you won’t have to replace them often.

| Feature | Ceramic Blades | Steel Blades |

|---|---|---|

| Initial Cost | Higher upfront cost | Lower upfront cost |

| Edge Retention | Longer lifespan | Requires frequent sharpening |

| Maintenance | Minimal (no rust) | Frequent (rust prevention) |

Disadvantages of Ceramic Blades

Brittleness and Risk of Chipping

Why it happens?

Ceramic blades are extremely hard, but this also makes them brittle. When exposed to sudden impact, drops, or twisting force, they are more likely to chip or crack.

Where it’s a problem?

Ceramic blades are not ideal for heavy-duty tasks that involve cutting through bones, frozen foods, or other hard materials. They work best for soft, precise cuts on items like fruits, vegetables, and lightweight textiles.

How to prevent it?

Handle ceramic blades with care and avoid contact with hard surfaces. Use a cutting board made of wood or plastic to avoid accidental chipping.

Limited Use Cases

Not suitable for heavy-duty cutting

Unlike steel blades, ceramic blades are not versatile enough to handle bones, frozen foods, or hard objects.

Lack of flexibility

Ceramic blades lack the flexibility of steel, which allows steel blades to bend and absorb impact. This makes ceramic blades ideal for precision cutting, but not for heavy-duty tasks.

Cost and Accessibility

Higher initial cost

Ceramic blades are more expensive than steel blades. This is because of the specialized manufacturing process required to create their hard, sharp edges.

Limited availability

While steel blades are readily available, ceramic blades are more specialized and may not be as accessible in certain regions or stores.

Sharpening and Maintenance

Challenging to sharpen: Ceramic blades require adiamond sharpener for proper sharpening, unlike steel blades that can be honed with a standard whetstone.

Sharpening frequency: Although ceramic blades maintain their sharpness much longer than steel, when they do become dull, they require professional sharpening services or specialized tools, which adds to the maintenance cost.

| Disadvantage | Impact on Use |

| Brittleness | Prone to chipping and cracking |

| Limited Use Cases | Cannot cut bones, frozen food, or hard items |

| High Cost | More expensive than steel |

| Challenging to Sharpen | Requires diamond sharpeners |

Pro Tip: If you’re buying ceramic blades, ensure you’re using them for the right tasks. Use them for precision cuts on soft materials like fruits, vegetables, and textiles. Avoid tasks that involve hard or frozen items to prevent chipping.

Ceramic Blades vs. Steel Blades

When it comes to choosing between ceramic blades and steel blades, understanding their differences can help you make the right decision for your specific needs. Each material has unique properties that make it ideal for certain tasks and less suitable for others.

Sharpness and Edge Retention

Sharpness: Ceramic blades are known for their razor-sharp edges, often sharper than most steel blades straight out of the box. This is due to the superior hardness of zirconium oxide, which allows ceramic blades to achieve a finer edge during the manufacturing process.

Edge Retention: One of the key advantages of ceramic blades is their ability to stay sharp for much longer than steel blades. In fact, ceramic blades can maintain their edge for up to 10 times longer than steel blades. This reduces the need for frequent sharpening, saving both time and effort.

Steel Blades: While steel blades can also be sharp, they tend to dull faster due to their lower hardness compared to ceramic. However, steel blades can be easily re-sharpened using standard sharpening tools, unlike ceramic blades, which require a diamond sharpener.

| Feature | Ceramic Blades | Steel Blades |

|---|---|---|

| Initial Sharpness | Sharper | Sharp, but not as sharp |

| Edge Retention | Up to 10x longer | Dulls faster |

| Ease of Sharpening | Requires diamond sharpener | Can be sharpened easily |

Key Insight: If you want a blade that stays sharp for long periods with minimal maintenance, ceramic blades are the superior choice. However, if you prefer a blade that can be easily re-sharpened when it dulls, steel blades are a more practical option.

Durability and Brittleness

Durability: While steel blades are tough and flexible, ceramic blades are harder but more brittle. This means that while ceramic blades resist wear and deformation, they are also more prone to chipping or breaking if dropped or subjected to lateral pressure.

Impact Resistance: Steel blades can withstand impacts and bending forces, making them ideal for tasks that require high durability, such as chopping bones or cutting through hard materials.

Ceramic Blades: Ceramic blades are more fragile due to their extreme hardness. While they perform exceptionally well for precision cuts on soft materials like fruits, vegetables, and textiles, they can chip or crack if used on hard objects or dropped on a hard surface.

| Feature | Ceramic Blades | Steel Blades |

| Durability | Brittle, can chip | Durable, flexible |

| Impact Resistance | Low | High |

| Best Use Case | Precision cutting | Heavy-duty cutting |

Pro Tip: If you’re working with soft items like fruits or textiles, ceramic blades are a great option. For hard materials like bones or frozen food, steel blades are the better choice due to their flexibility and resistance to breakage.

Rust and Corrosion Resistance

Rust Resistance: Unlike steel, which can rust if exposed to moisture, ceramic blades are completely rust-proof. This is because ceramic is a non-metallic material that does not react with water or oxygen.

Corrosion Resistance: Ceramic blades also do not corrode, even when exposed to acidic or salty substances. This makes them ideal for kitchen use, especially when cutting citrus fruits or tomatoes, where acidic juices may corrode steel blades over time.

Steel Blades: Traditional steel blades are susceptible to rust unless they are made from stainless steel. Even stainless steel blades require proper maintenance, such as drying after washing, to prevent rust and corrosion.

| Feature | Ceramic Blades | Steel Blades |

| Rust Resistance | 100% rust-proof | Can rust if not stainless |

| Corrosion Resistance | Yes | Prone to corrosion (unless stainless) |

| Best Use Case | Wet or acidic environments | General use |

Did You Know? If you frequently cut acidic fruits like lemons or limes, a ceramic blade is a better option. It won’t rust or corrode, unlike steel blades, which may develop stains or corrosion spots.

Weight and Handling

Weight: Ceramic blades are significantly lighter than steel blades. This is due to the lightweight nature of zirconium oxide compared to steel alloys.

Ergonomics: The lighter weight of ceramic blades makes them easier to handle, especially for extended use. This reduces wrist and hand fatigue, which is beneficial for precision tasks in kitchen work, crafting, and industrial cutting.

Steel Blades: Steel blades are heavier, but this added weight can provide more cutting power. For example, a heavier knife requires less effort to chop through dense or hard materials.

| eature | Ceramic Blades | Steel Blades |

| Weight | Lightweight | Heavier |

| User Fatigue | Minimal fatigue | Can cause fatigue |

| Best Use Case | Precision cutting | Heavy-duty chopping |

Expert Opinion: For tasks requiring fine, repetitive cuts, ceramic blades are preferred due to their lightweight design. For high-force cuts, such as cutting through dense materials, steel blades are better suited.

Summary of Ceramic Blades vs. Steel Blades

| Feature | Ceramic Blades | Steel Blades |

| Sharpness | Sharper initially | Sharp, but dulls faster |

| Edge Retention | Up to 10x longer | Requires frequent sharpening |

| Durability | Brittle, can chip | Durable, flexible |

| Rust/Corrosion Resistance | Rust-proof | Rust-prone unless stainless |

| Weight | Lightweight | Heavy |

| Impact Resistance | Low | High |

| Ease of Sharpening | Requires diamond sharpener | Easily sharpened |

Final Verdict: Ceramic blades are ideal for tasks that prioritize sharpness, edge retention, and rust resistance. Steel blades are better for impact resistance, flexibility, and heavy-duty cutting

Use Cases for Ceramic Blades

Ceramic blades excel in specific applications due to their sharpness, rust resistance, and long-lasting edge retention. Here are some of the most common use cases where ceramic blades outperform traditional steel blades.

Kitchen Use

Food Preparation: Ceramic kitchen knives are widely used for cutting fruits, vegetables, and boneless meats. Their sharp edges allow for precise, clean cuts without crushing or bruising the food. Since ceramic blades are resistant to rust and corrosion, they are perfect for use in wet environments like kitchens.

Non-Reactive Material: Unlike steel blades, ceramic blades do not react with acidic foods, such as lemons, tomatoes, or limes. This ensures no metallic taste or discoloration of the food, making them ideal for meal prep.

Easy to Clean: Since ceramic blades are non-porous, they do not absorb food particles, stains, or bacteria. This makes them more hygienic and easier to clean than steel blades.

Example: If you’re preparing fruits like apples or pears, ceramic blades are perfect since they maintain the fruit’s natural color and taste, unlike steel blades which may react with the fruit’s acids.

Industrial and Manufacturing Use

Textile Cutting: Ceramic blades for textile cutting are preferred in the textile industry. Their sharpness and long edge retention allow for smooth, precise cuts in fabrics, reducing fabric waste and improving production efficiency.

Packaging and Film Cutting: Ceramic blades are widely used in industries that require cutting through thin films, plastic wrap, and packaging materials. Their precision ensures a clean, straight cut every time.

Durability in Production Lines: Ceramic blades last significantly longer than steel blades, reducing downtime for blade replacements. Their resistance to wear and tear makes them essential for manufacturing and assembly lines where continuous cutting is required.

Example: Many industrial cutting tools in the textile industry use ceramic blades because they provide cleaner cuts, which is essential for high-precision textile manufacturing.

Medical and Surgical Use

Medical Instruments: Ceramic blades are used in medical applications where precision and hygiene are critical. Their non-reactive nature ensures there is no risk of contamination.

Surgical Blades: Since ceramic blades remain sharper for longer, they are sometimes used in surgical tools for precision cuts on delicate tissues.

Non-Conductive Properties: Unlike metal blades, ceramic blades are non-conductive, making them suitable for use around sensitive medical equipment.

Example: In certain surgical procedures, ceramic medical blades are preferred over metal blades to avoid contamination and maintain higher hygiene standards.

Crafting and Hobby Use

Arts and Crafts: For crafting activities like paper cutting, stencil making, and model building, ceramic utility knife blades are a popular choice. Their sharp edges enable detailed, intricate cuts.

Hobbyist Use: Crafters working with fabric, leather, or cardboard often choose ceramic blades for their precision. Unlike metal blades, ceramic blades maintain their sharpness even after repeated use.

Safety Benefits: Many ceramic craft blades come with safety features, like finger-friendly edges, to prevent accidental cuts.

Example: When creating paper stencils for DIY art projects, crafters use ceramic blades to achieve precise, detailed cuts with minimal effort.

Electronic and Laboratory Use

Non-Conductive Blades: Since ceramic blades do not conduct electricity, they are widely used in electronics manufacturing and repair. They are safe to use around circuits and sensitive electrical components.

Chemical Resistance: In laboratory environments where exposure to harsh chemicals is common, ceramic blades are a top choice. Their resistance to chemical corrosion makes them more reliable than steel blades in such environments.

Laboratory Use: Laboratories use ceramic blades in precision cutting of delicate materials like gels, plastics, and certain biological samples.

Example: In electronics manufacturing, non-conductive blades prevent accidental electrical short circuits, making ceramic blades a safer option for technicians.

Personal Use and Everyday Tasks

Home Use: Many households use ceramic knives for daily kitchen prep because they require less sharpening and are resistant to stains, rust, and corrosion.

Safe for Children: Some ceramic craft knives are designed with child-safe blades that are sharp enough to cut paper but not skin. This makes them useful for DIY projects involving children.

Gift Items: Many people purchase ceramic knives as gifts because they are seen as premium kitchen tools that require minimal maintenance

Example: Parents often choose ceramic craft knives for kids’ DIY projects, as some are designed to cut paper and cardboard safely but not skin.

Summary of Use Cases for Ceramic Blades

| Use Case | How Ceramic Blades Are Used | Why Ceramic Blades Are Better |

|---|---|---|

| Kitchen Use | Cutting fruits, vegetables, boneless meats | Rust-resistant, non-reactive, hygienic |

| Industrial Use | Textile, packaging, and film cutting | Sharp, long-lasting, precise cuts |

| Medical Use | Medical instruments, surgical tools | Non-conductive, hygienic, precise cuts |

| Crafting and Hobby | Arts, crafts, fabric, paper cutting | Sharp edges, child-safe options |

| Electronics Use | Electronics repair and assembly | Non-conductive, safe to use near circuits |

| Everyday Use | Household knives, child-safe DIY blades | Rust-proof, long-lasting sharpness |

How to Care for and Maintain Ceramic Blades

Caring for ceramic blades is essential to ensure they stay sharp, avoid chipping, and maintain their long lifespan. While they require less maintenance than steel blades, they do need special attention due to their brittleness.

Proper Cleaning Methods

- Hand-Washing Only: Unlike steel blades, ceramic blades should not be cleaned in a dishwasher. The high pressure and vibrations in dishwashers can cause them to chip or crack. Instead, wash them by hand with mild soap and warm water.

- Avoid Abrasive Scrubbers: Avoid using rough sponges, steel wool, or abrasive pads as they can wear down the surface of the blade. A soft sponge or cloth is ideal.

- Dry Thoroughly: Although ceramic blades are rust-proof, it’s still good practice to dry them thoroughly to avoid moisture spots or water stains.

Pro Tip: If you’re traveling or transporting ceramic blades, use a padded knife roll or case to prevent impact damage during transit.

Safe Storage Tips

- Use a Blade Guard or Sheath: Since ceramic blades are more brittle than steel, it’s best to store them in a protective blade guard, knife block, or dedicated slot in a knife organizer.

- Avoid Storing in Drawers: Tossing ceramic blades in a kitchen drawer with other utensils can result in chips and cracks. Always store them separately to prevent impact damage.

- Protect the Edges: If a blade guard is unavailable, wrap the blade’s edge in a soft cloth before storing it to avoid accidental chips.

Example: Parents often choose ceramic craft knives for kids’ DIY projects, as some are designed to cut paper and cardboard safely but not skin.

Sharpening Ceramic Blades

Unlike steel blades, ceramic blades require specialized sharpening tools to restore their sharp edges. This is due to their extreme hardness, which makes standard sharpening tools ineffective.

- Use a Diamond Sharpener: Only a diamond sharpener is strong enough to sharpen ceramic blades. Traditional sharpening stones or honing rods used for steel blades will not work on ceramic.

- Sharpen Infrequently: Ceramic blades stay sharp for much longer than steel, often up to 10 times longer. This means you’ll rarely need to sharpen them.

- Professional Sharpening Services: If you don’t have access to a diamond sharpener, consider using professional sharpening services. Many kitchenware retailers offer this service for ceramic kitchen knives.

Pro Tip: If you decide to sharpen ceramic blades yourself, make sure to follow the sharpener’s instructions carefully. Ceramic blades can chip if they’re not sharpened at the correct angle.

Summary of Care and Maintenance Tips

| Task | What to Do | What to Avoid |

|---|---|---|

| Cleaning | Hand-wash with mild soap | Avoid dishwashers and abrasive pads |

| Storage | Use blade guards, knife blocks, or sheaths | Do not store loose in drawers |

| Sharpening | Use a diamond sharpener | Do not use traditional whetstones |

| Cutting Surface | Use wood or plastic cutting boards | Avoid glass, stone, or metal surfaces |

| Usage Restrictions | Use for soft materials (fruits, vegetables) | Do not cut bones, frozen food, or metal |

Key Takeaway: With proper cleaning, storage, and sharpening, ceramic blades can maintain their sharpness and quality for years. By avoiding impact damage and using the right cutting surfaces, you’ll protect your investment in these precision tools.

Frequently Asked Questions (FAQ) About Ceramic Blades

Are ceramic blades better than steel blades?

It depends on the application. Ceramic blades are sharper, stay sharp longer, and resist rust and corrosion. However, they are more brittle and can chip or crack with impact, unlike steel blades that are more flexible and durable.

How long do ceramic blades stay sharp?

Ceramic blades can stay sharp up to 10 times longer than steel blades. This is due to their extreme hardness, which prevents the edge from dulling as quickly as metal blades.

Can ceramic blades be used to cut bones or frozen food?

No, ceramic blades are not designed to cut hard materials like bones or frozen food. These tasks require the flexibility and impact resistance of steel blades to avoid chipping or cracking the ceramic edge.

How do I sharpen a ceramic blade at home?

Ceramic blades require a diamond sharpener to restore their edge. Follow these steps:

- Hold the blade at a 20-degree angle against the sharpener.

- Slide the blade gently across the diamond surface, maintaining the same angle.

- Repeat this process on both sides until the edge is sharp.

If you’re not confident, consider using a professional sharpening service.

Are ceramic blades safer than steel blades?

While ceramic blades are sharper, some manufacturers produce ceramic blades with a finger-friendly edge to reduce the risk of cuts. However, if misused, ceramic blades can still cause injury, so proper handling is essential.

Do ceramic blades rust or corrode?

No, ceramic blades are 100% rust-proof and corrosion-resistant. Unlike steel blades, they do not react to moisture, acidic substances, or exposure to water.

Can ceramic blades cut through hard materials like glass or stone?

No, ceramic blades are not suitable for cutting hard materials like glass, metal, or stone. The hardness of ceramic makes it prone to chipping or breaking when exposed to high-impact tasks.

What materials should I avoid cutting with a ceramic blade?

Avoid using ceramic blades to cut:

- Bones

- Frozen food

- Metal or glass objects

- Thick, hard plastics

These materials are too hard and may cause the ceramic blade to chip or break.

Can ceramic blades be used for medical or laboratory applications?

Yes, ceramic blades are widely used in medical instruments and laboratory settings. Their non-reactive, rust-resistant properties make them ideal for hygienic environments.

Are ceramic blades worth the investment?

Yes, if you need a blade that stays sharp for a long time, resists rust, and requires minimal maintenance. Ceramic blades last longer and provide more precise cuts, especially for food preparation, textile cutting, and crafting.

Conclusion

Ceramic blades excel in sharpness, edge retention, and rust resistance, making them ideal for precision tasks. While not suited for heavy-duty cutting, they offer unmatched longevity and low maintenance, making them a top choice for kitchens, crafting, and medical tools.